SuperPro Anti-Roll Bars

For sharper steering, better handling and more grip for all driving situations.

Your everyday car can easily be enhanced with SuperPro anti-roll bar products (also known as sway bars, anti-sway bars or stabilizer bars) for sharper steering, less body roll - making it safer for driver and passengers.

The SuperPro anti-roll bar range includes:

- Anti-roll bars: featuring SuperPro's unique proprietary ultra-durable coating and designed and built in-house.

- Roll-centre correction products

- Caster, camber and toe alignment kits

- Anti-lift products

Why use anti-roll bars, sway bars or, stabiliser bars?

There are many reasons, however the prime reason a bar is fitted is to maintain maximum tyre contact with the road. Suspension systems are designed to vary the angle of the wheel and contact patch as a vehicle travels along the road. The optimum contact patch is achieved with the wheel in the vertical position. Braking, body roll, body yaw, squat and dive all cause the shift in contact patch.

SuperPro’s superior manufacturing and technological expertise ensures better car performance and safety when cornering. SuperPro anti-roll bars ensure that the load is distributed evenly over your tyres delivering longer tyre life and a better grip leading to a more comfortable driving experience.

Why Choose a SuperPro Anti-Roll Bar?

SuperPro Roll Bars are made from two grades of steel depending on the manufacturing process.

- Hot-Formed Roll Bars - Bars that are made in this process are made from 55CR3 Spring Steel. This steel is purposely designed for coil springs, torsion bars and suits perfectly for the manufacture of sway bars. After hot forming, the sway bars are heat treated by Quenching and Tempering to achieve the mechanical properties of Yield, Hardness and Tensile strength conducive to use as an Automotive Roll Bar.

- Cold-Formed Roll Bars - Bars that are made in this process are made from XK5160RP Spring Steel. This is a medium to high carbon-chromium spring steel possessing high hardness used predominantly in manufacture of coil & leaf springs. Cold forming of these sway bars does not alter the mechanical properties of the material, so therefore no heat treating process is required. In addition, the steel used in this method is best suited to be cold bent and the mechanical properties are the same as the hot formed bars after heat treatment.

SuperPro choose the best material for the given manufacturing process to achieve the best outcome. When stamping and forming the ends of our cold bent bars SuperPro keep our forging temperatures as low as possible to avoid altering the mechanical properties of the steel. This process is made much easier by using an induction heater.

We should also mention our 3-step coating process (sand blasted, zinc plated & corrosion resistant paint) that, we have been informed from external sources, rivals Detroit O.E standard. With over 4000 hours of Salt spray testing and no degrading of the surface finish, this highlights another superior feature of SuperPro Roll Control Sway Bar.

SuperPro Adjustable Anti-Roll Bars

Adjustable anti-roll bars put you in control of the rigidity of the bars by allowing you to adjust the length of the arms. The adjustable anti-roll bars come 2, 3 or 4 points of adjustment providing numerous stiffness options. These anti-roll bars reduce the need to replace the entire anti-roll bar with multiple different designs.

SuperPro Hollow Anti-Roll Bars

For the last decade manufacturer’s have focussed a great deal on reducing vehicle mass to decrease fuel consumption, which has led to research into more effective lightweight metals. This has resulted in hollow anti-roll bars that, through careful selection of choice of materials, facilitates progressive performance characteristics for even more sophisticated tuning and suspension setups.

SuperPro hollow anti-roll bars are up to 30% lighter than the traditional bars and are made from race spec chromoloy. These progressive roll control bars provide reduced weight and better fuel efficiency. Features of SuperPro hollow bars include:

- 30% lighter – reduced unsprung mass *

- Race-spec chromoly

- Unique progressive design

- Fully adjustable to suit a variety of different vehicle configurations and uses

* When compared with OE and aftermarket alternatives

Aren't hollow anti-roll bars less stiff than solid bars?

An anti-roll bar operates in a cross-sectional plane offering torsional resistance to twist. Simply making a sway bar thicker makes the torsional resistance greater and therefore the anti-roll bar becomes stiffer.

Tubular material works just like a solid bar using material cross-section torsional-resistance. With a tubular anti-roll bar design, anti-roll rate or resistance can be adjusted by changing both the outside diameter and wall thickness which means that you can achieve the same characteristics as a solid bar with careful development and testing - which SuperPro do in-house in their own facilities in Brisbane Australia.

See what we do for your vehicle

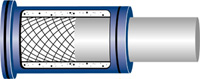

SuperPro Anti-Roll Bar Bushes

Knurling is used to enable unrestricted pivoting of the polyurethane bush around the anti-roll bar. The knurling has two inherent design advantages. The knurling reduces the surface area of polyurethane in contact with the crush tube. This reduction in surface area results in less frictional forces being developed. The SuperPro knurl bore keeps the lubricating grease intact for the life of the bushing, and eliminates the necessity for periodic re-greasing. All SuperPro anti-roll bars come with SuperPro's anti-roll bar bushes (where needed) but they are also available to purchase separately for your standard or aftermarket roll bars.

Knurling is used to enable unrestricted pivoting of the polyurethane bush around the anti-roll bar. The knurling has two inherent design advantages. The knurling reduces the surface area of polyurethane in contact with the crush tube. This reduction in surface area results in less frictional forces being developed. The SuperPro knurl bore keeps the lubricating grease intact for the life of the bushing, and eliminates the necessity for periodic re-greasing. All SuperPro anti-roll bars come with SuperPro's anti-roll bar bushes (where needed) but they are also available to purchase separately for your standard or aftermarket roll bars.

Abarth

Abarth Alfa Romeo

Alfa Romeo Asia Motors

Asia Motors Aston Martin

Aston Martin Audi

Audi Austin

Austin Austin-Healey

Austin-Healey Bentley

Bentley BMW

BMW Chevrolet

Chevrolet Chrysler

Chrysler Citroen

Citroen Daewoo

Daewoo Daihatsu

Daihatsu Daimler

Daimler DMC

DMC Dodge

Dodge Ferrari

Ferrari Fiat

Fiat Ford

Ford Ginetta

Ginetta Hillman

Hillman Holden

Holden Honda

Honda Hummer

Hummer Hyundai

Hyundai Indigo

Indigo Infiniti

Infiniti Isuzu

Isuzu Jaguar

Jaguar Jeep

Jeep Jensen

Jensen Kia

Kia Lancia

Lancia Land Rover

Land Rover LDV

LDV Lexus

Lexus Lotus

Lotus Mahindra

Mahindra Maserati

Maserati Mazda

Mazda Mercedes-Benz

Mercedes-Benz MG

MG Mini

Mini Mitsubishi

Mitsubishi Morris

Morris Nissan

Nissan Noble

Noble Opel

Opel Peugeot

Peugeot Porsche

Porsche Proton

Proton Reliant

Reliant Renault

Renault Rootes Group

Rootes Group Rover

Rover Saab

Saab Seat

Seat Singer

Singer Skoda

Skoda Smart

Smart Ssangyong

Ssangyong Subaru

Subaru Sunbeam

Sunbeam Suzuki

Suzuki Talbot

Talbot Tata

Tata Tesla

Tesla Toyota

Toyota Triumph

Triumph TVR

TVR Vauxhall

Vauxhall Volkswagen

Volkswagen Volvo

Volvo